Plastic Laser Cutting Services

High Precision Plastic Laser Cutting

Plasticut is an Australian-owned and operated manufacturer with Perspex, but we also provide a range of fabrication processes that include Laser Cutting. This is a highly precise and accurate process that uses a computer-directed laser to cut very intricate shapes and small holes in flat sheets of plastic, yielding a perfect result every time.

We manage your project from start to finish, starting with the design and ending with delivery to your warehouse in Australia or worldwide. Our technical expertise and professional engineering solutions ensure you receive high-quality, consistent products with a fast turnaround.

What is Plastic Laser Cutting?

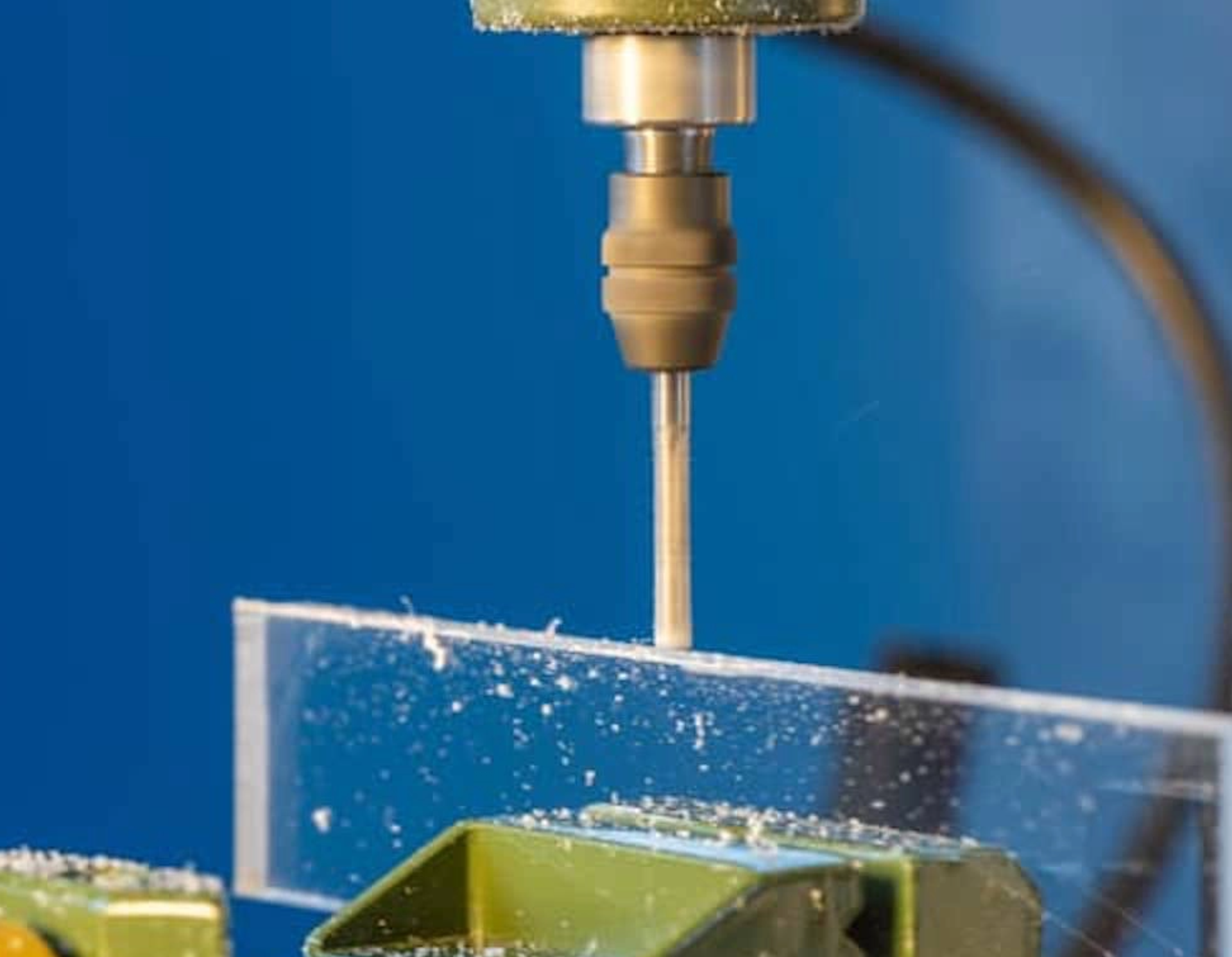

Laser Cutting is a method that creates shapes cut from flat sheets of plastic, resulting in an accurate, precise and extremely clean finish. It’s often used to produce engravings or stencils and lends itself well to creating complex contours or small holes with clean-cut edges and a high level of precision. With Laser Cutting, there’s no need for further machining to finish the edges and remove burrs, as this process eliminates these imperfections.

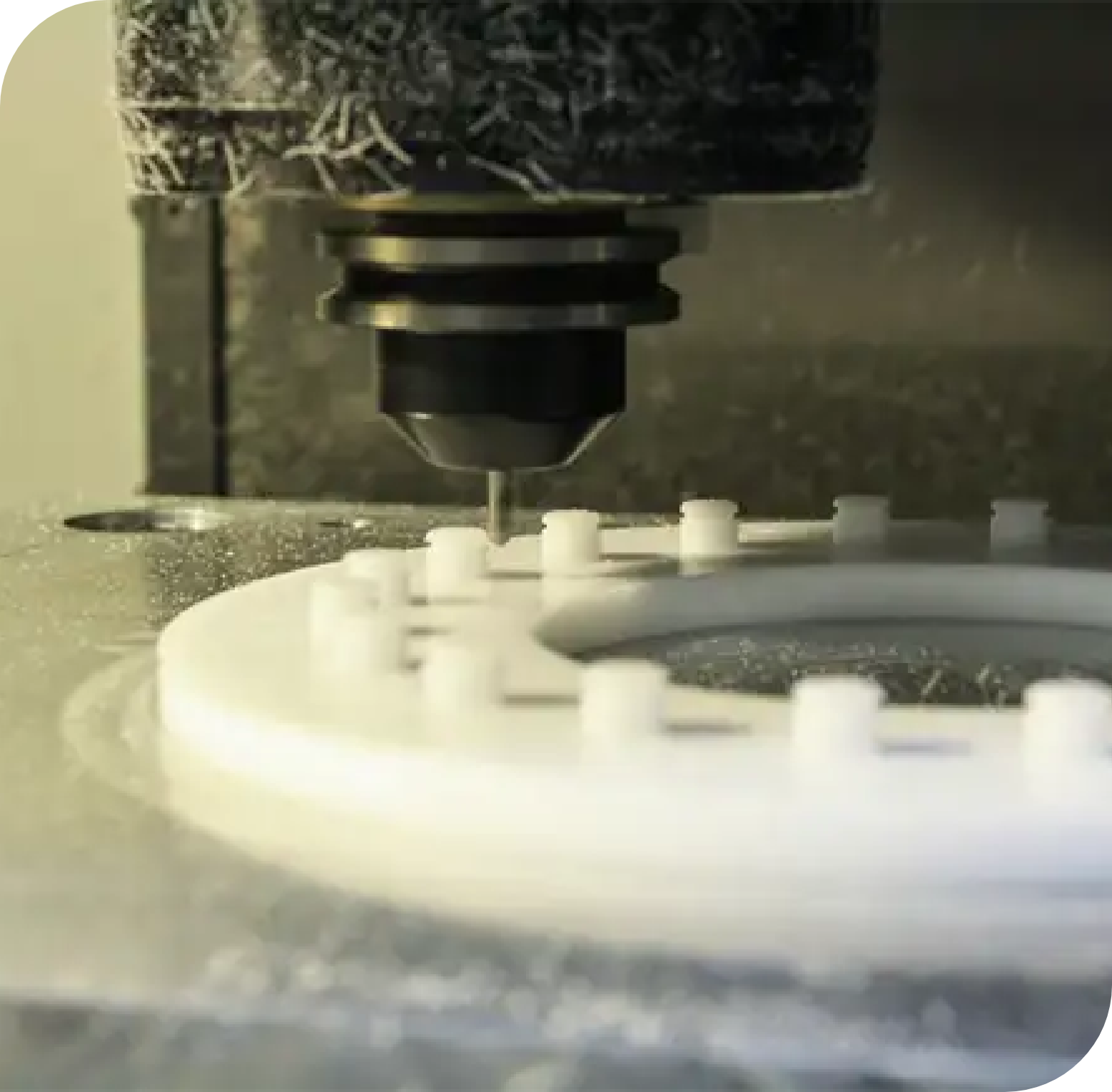

Given that laser cutters use heat to slice through the plastics, it can only be used to cut a limited number of plastics, including the following:

- PETP.

- PTFE.

- Acrylic.

- Nylons.

Laser Cutting is often used to create decorative, stencilled wall coverings or room partitions, candle holders, tables, chairs and lights. It’s popular with interior designers, architects, design firms and other creative companies. It can be used to etch words in plastic, produce parts for medical devices, computers and electronics, creates promotional items, door signage and much more. If you want clean-cut edges, bespoke designs and a fast turnaround, then consider Laser Cutting for your next project.

Laser Cutting produces finished designs with unprecedented accuracy and complex patterns. This is a non-contact process with little wastage, high tolerances and exceptionally smooth finishes. It’s a fast, precise and efficient process.

- Little wastage.

- High-precision and exceptionally fine cuts.

- Smooth and clean-cut edges.

- Fast turnaround.

- No additional finishing required.

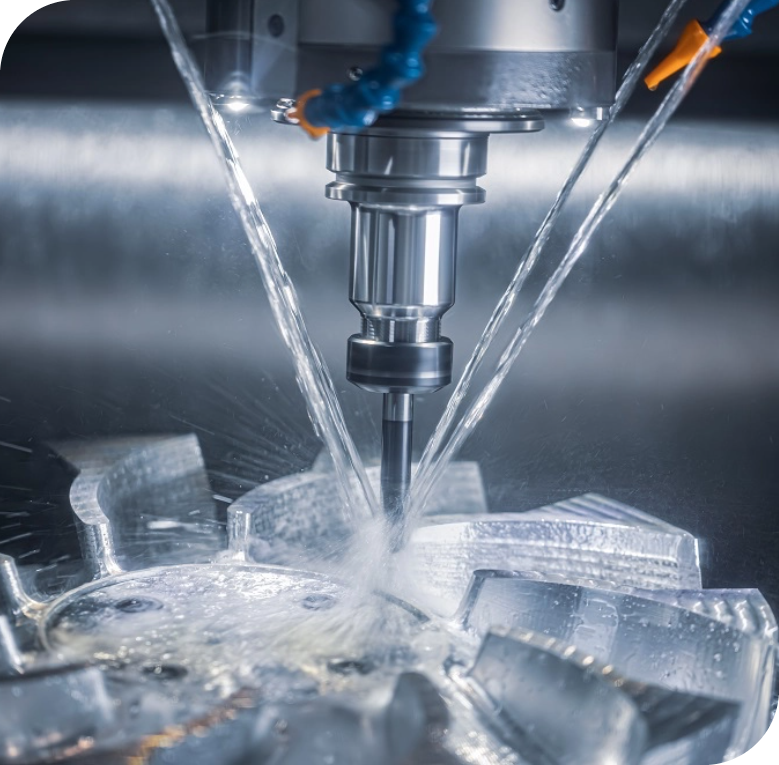

Laser Cutting and CNC Routing are both computer-driven processes that result in high-precision cuts and intricate shapes that are replicated consistently and accurately. They are both reliable, fast and cost-effective strategies for cutting, etching or engraving plastics.

Laser Cutting, however, produces much finer and more detailed cuts than CNC Routing, simply because it uses a high-powered laser to make the cuts. It also results in a clean polished edge that’s perfect for many applications.

Plasticut is proudly Australian-owned and operated. For the past 40 years, we have manufactured with Perspex and provided a range of plastic fabrication processes, including Laser Cutting. We can produce anything from single prototypes to thousands of items, delivered around Australia or worldwide.

- Proudly Australian-owned and operated.

- Perspex manufacturer, specialising in Laser Cutting.

- Extensive stock of plastics onsite.

- Advanced Laser Cutting technology.

- Fast turnaround times.

- Friendly Customer Service.

- State-of-the-art Melbourne workshop.

- Obligation-free quotes.

To find out if Laser Cutting is suitable for your parts or components, contact the team on 03 9357 6688 or send us an email enquiry.