Conventional Machining

Conventional Machining - Melbourne

Plasticut is the leading plastic fabricator in Melbourne, supplying a range of services to residential, commercial, industrial and DIY customers around Australia. Whilst one of our widely used services is CNC machining, we also offer a conventional machining process on an as-needed basis.

If you’re not sure which type of machining you need, whether a CNC or conventional process, just give us a call and we’ll provide you with all the advice you need to make the right decision for your project.

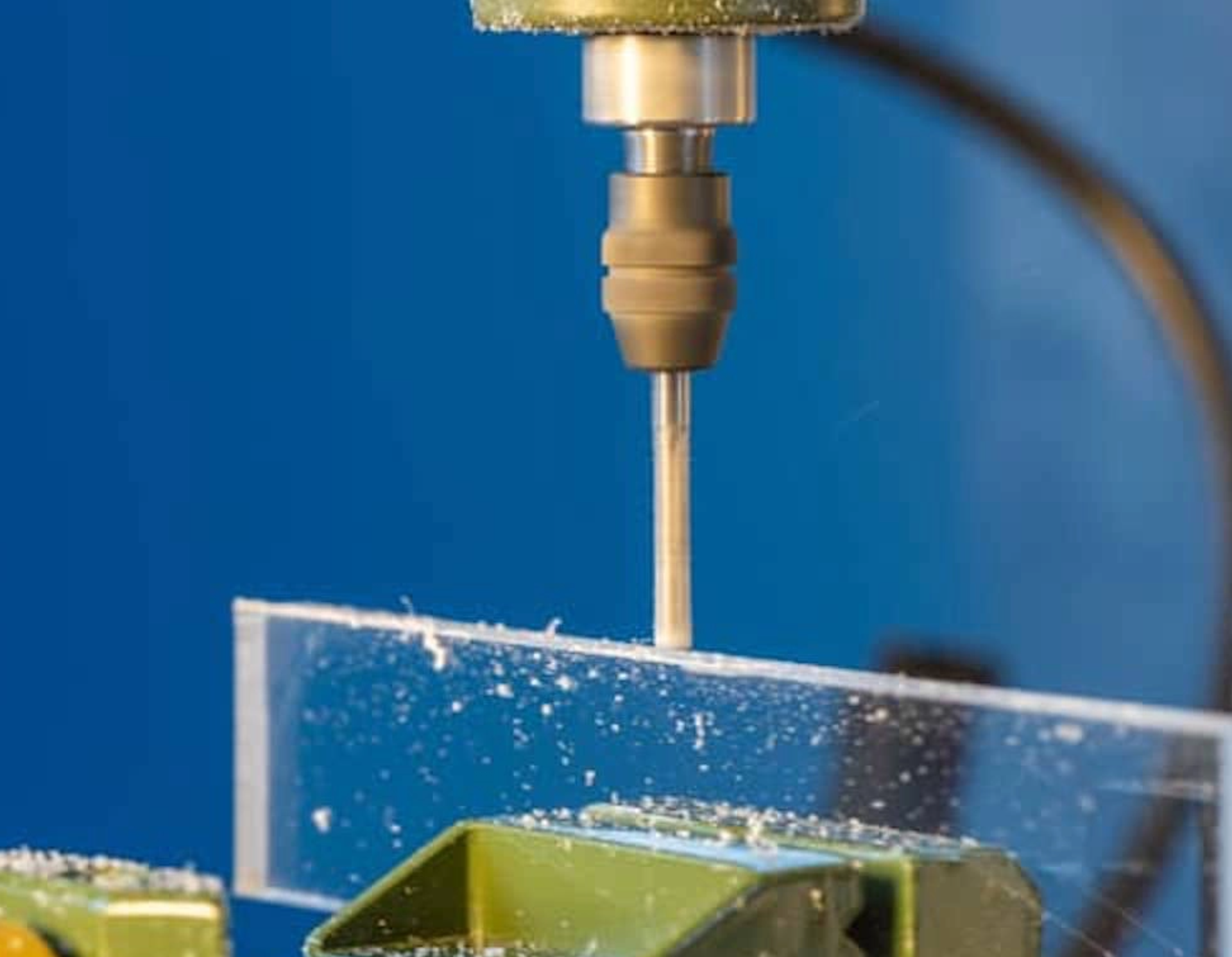

What is a conventional machining process?

In many ways, the progress from a conventional machining process to CNC machining is due to technological advances and the increasing need for high precision components with tight tolerances. Yet, many of our customers still request conventional machining for their plastic components – why is this?

It’s often because conventional machining doesn’t require expensive computers and software, so it’s not as expensive as CNC machining. Instead the process is managed by skilled employees where the operator decides when the equipment needs to be moved, where it needs to be moved and when it needs to be stopped. The precision of the machining and the quality of the component or end product is dependent on the skills and experience of the operator.

The conventional machining process is generally used for small runs or a single part, not only because it’s so heavily labour intensive but also due to its operator dependency. This means that the ability to manufacture exact replicates in volume is extremely low. Therefore, if highly precise, multiple copies are needed, CNC machining is your best option.

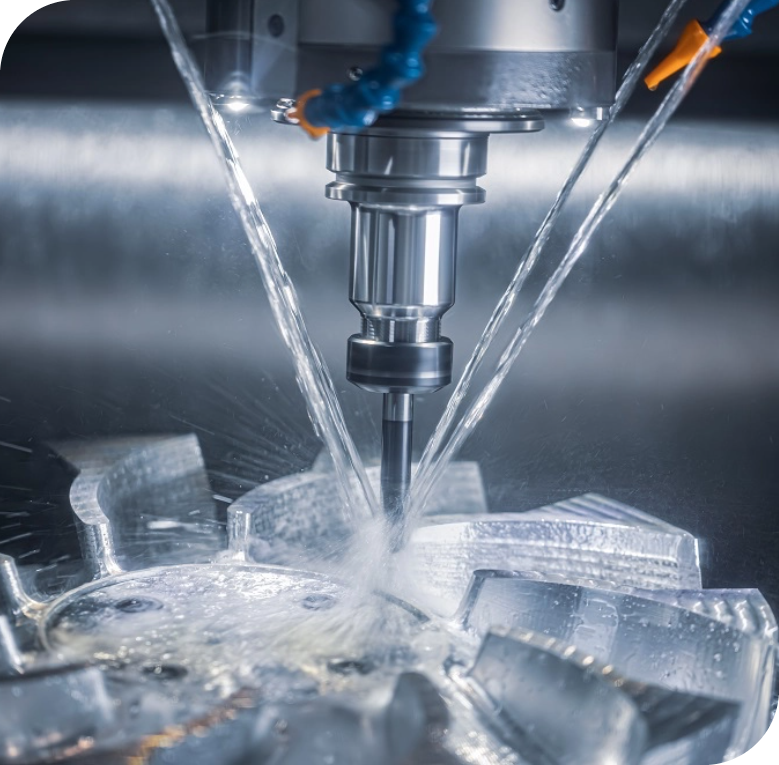

How does CNC machining compare?

The CNC machining process is more efficient and is therefore, more affordable than conventional machining. The design, measurements and parameters are all managed by the software, resulting in highly precise cuts, low tolerances and perfect replicates.

CNC machining a very cost-effective option that’s perfect for producing exact replicates. It’s also the process of choice for large volume runs.

Materials

The following plastic materials can be used in both CNC and conventional machining processes.

- Polyethylene

- Acetal

- Nylons

- Acrylic

- PETP

- Polypropylene

- PTFE

- PVC

- Advanced Engineered Plastic

- Polycarbonate

Why choose conventional machining? Well, if your project involves turning, milling, boring, drilling or cutting plastics and you want a prototype produced or just a small run, then this is your best option, particularly if your budget is limited.

With more than 40 years in the plastic fabrication industry, we have never forgotten our roots and still offer our customers traditional machining services.

- Australian-owned and operated company.s

- More than 40 years in the industry.

- CNC and conventional machining processes.

- Large stock of premium plastics available.

- Friendly customer service.

- Fast turnaround times.

- Affordable prices.

- Obligation-free quotes.

For more information about ordering cut-to-size plastic from our Melbourne factory, contact the team on 03 9357 6688 or send us an email enquiry.